Charakteristikos mūsų 1000 vatų lazerinis aparatas

1. Šviesos kelio sistemos ir valdymo sistemos stabilumas ir patikimumas

2. Importuoti originalūs pluošto lazeriai, aukštos ir stabilios funkcijos, eksploatavimo trukmė yra daugiau nei 100 000 valandų

3. Aukštesnė pjovimo kokybė ir efektyvumas, pjovimo greitis iki 80 m/min, išvaizda ir graži pjovimo briauna

4. Vokiškas didelio našumo reduktorius, pavara ir stovas; japoniškas kreiptuvas ir rutulinis varžtas.

Taikoma pramonė ir medžiagos pluošto lazeriu pjaustymo mašina

pluošto lazeriu pjaustymo mašina taikymas:

metalo pjovimas, elektros jungiklių gamyba, aviacija, maisto mašinos, tekstilės mašinos, inžinerinės mašinos, lokomotyvų gamyba, žemės ūkio ir miškininkystės mašinos, liftų gamyba, specialiosios transporto priemonės, buitinė technika, įrankiai, apdirbimas, IT gamyba, naftos mašinos, maisto mašinos, deimantiniai įrankiai , suvirinimas, suvirinimo įranga, metalo medžiagos, dekoravimo reklama, paviršių apdorojimas lazeriu užsienio apdirbimo paslaugų, tokių kaip visų rūšių mašinų apdirbimo pramonė.

Mūsų pluošto lazeriu pjaustymo mašinaTaikymo medžiaga:

Profesionalus, naudojamas pjaustyti ploną lakštinį metalą, pjaustant įvairius aukštos kokybės 0,5–3 mm anglies plieno lakštus, taip pat gali būti pjaustomas nerūdijančio plieno plokštes, aliuminio lydinio plokštes, cinkuotą lakštą, elektrolitinę plokštę, silicio plieną, titano lydinį, aliuminio cinko plokštę. ir kitas metalas.

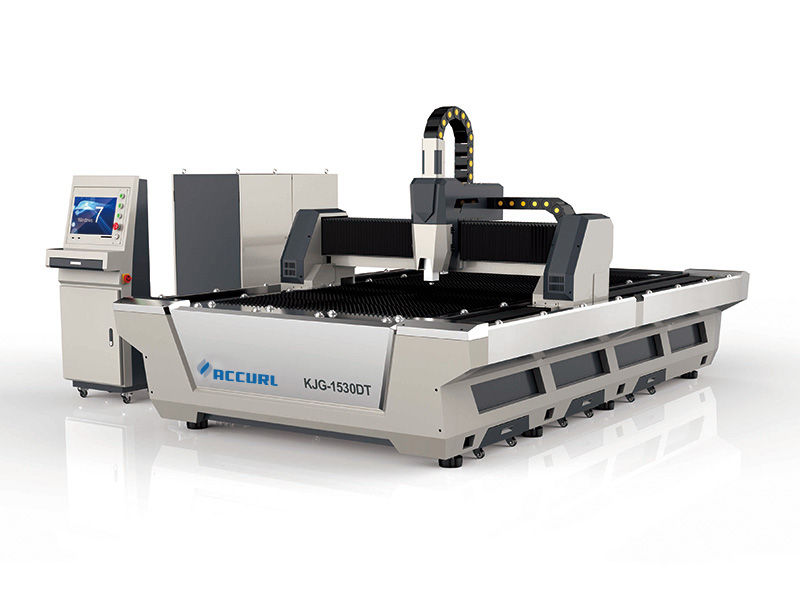

Pagrindinės mašinos nuotraukos 1kw lazerinio pjovimo mašina

Greita išsami informacija

Taikymas: Pjovimas lazeriu

Būklė: Nauja

Lazerio tipas: pluošto lazeris

Taikoma medžiaga: metalas

Pjovimo storis: 0-20mm

Pjovimo plotas: 1300 * 2500mm

Pjovimo greitis: 25m / min

CNC arba ne: Taip

Aušinimo režimas: vandens aušinimas

Valdymo programinė įranga: bechoff (Cypcut)

Palaikomas grafinis formatas: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Sertifikavimas: CE, ISO, SGS

Teikiamos garantinio aptarnavimo paslaugos: inžinieriai gali aptarnauti mašinas užsienyje

Modelis: 1000 vatų lazeris

Pjovimo medžiagos: nerūdijantis plienas anglinis plienas ir tt (metalo lazerinio pjovimo mašina)

Skaidulinio lazerio generatoriaus tipas: žinomas prekės ženklas Raycus (pagaminta Kinijoje)

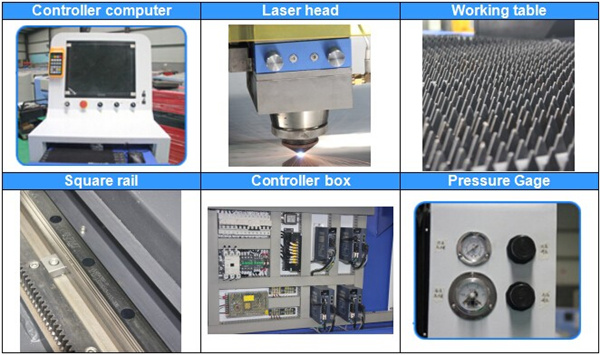

Pluošto lazerio pjovimo galvutė: Lasermech (iš JAV)

Varikliai ir tvarkyklės: 1500 W Fuji servo variklis, pagamintas Japonijoje

Min. Linijos plotis: ±0,02 mm

Pluošto modulio tarnavimo laikas: daugiau nei 100 000 valandų

Garantijos laikas: Visa mašina 3 metai (fib

Mūsų parametras Pluošto lazeriu pjaustymo mašina

| Mašinos modelis | 2500 * 1300 mm |

| Lazerio galia | 300W/500W/1000W/3000W |

| Skaidulinio lazerio generatoriaus tipas | Garsus prekės ženklas Raycus (pagaminta Kinijoje) |

| Lazerio bangos ilgis | 1064nm |

Lazerio pluošto kokybė | <0,373mrad |

| Darbinis stalas | Pjūklas |

| Pluošto lazerio pjovimo galvutė | Lasermech (iš JAV) |

| Fokusavimo objektyvas | Lasermech pagamintas JAV |

| Pluošto modulio eksploatavimo laikas | Daugiau nei 100000 valandų |

| Varikliai ir vairuotojai | 1500W Fuji servo variklis pagamintas Japonijoje |

| Reduktorius | 3 komplektai is Vokietijos |

| Vadovo bėgiai | Didelio tikslumo PMI prekės ženklas iš Taivano |

| Perdavimo sistema | Dvigubo krumpliastiebo tipo |

| Rack sistema | Vokietijos stovas |

| Grandininė sistema | Igus pagamintas Vokietijoje |

| Vandens aušintuvas | TEYU (S&A) prekės ženklas, CW6000 |

| Valdymo sistema | Profesionali lazerio valdymo sistema - „Cypcut“

|

| Padėties tipas | Raudonas taškas |

| Pjovimo storis | ≤ 3 mm (nerūdijantis plienas) ≤ 6 mm (anglies plienas) |

| Maks. Tuščiosios eigos greitis | 1400 mm/s |

| Pjovimo greitis | 300 mm/s |

| Padėties tikslumas | ± 0,05 mm / m |

| Padėties greitis | 20m / min |

| Min. Linijos plotis | ± 0,02 mm |

| Energijos sąnaudos | ≤12KW |

| Nešioti svorį | 700 kg |

| Įtampa | 380V/50HZ,3PH |

| Pagalbinės dujos pjaustymui | Deguonis, azotas, oras |

| Suderinama programinė įranga | „Autocad“, „Coreldraw“ ir kt |

| Grafinis formatas | Nc |

| Darbo metodas | PC valdymas |

| Bendras galios apsaugos įvertinimas | IP54 |

| Mašinos svoris | Apie 4000 kg |

| Mašinos dydis | 4800*2600*1800mm |

| Garantijos laikas | Visa mašina 3 metams (pluošto modulis 2 metai) |

1000 vatų lazerio kokybės kontrolė

Kokybė yra mūsų nuoširdžiausia pagarba visiems mūsų klientams, ir tai yra svarbiausias veiksnys norint palaikyti ilgalaikius verslo santykius su mumis.

Visada daugiau dėmesio skiriame lazerinio pjovimo staklių kokybei. Standartinė kokybės kontrolės sistema ir komanda yra atsakingi už gaminio kokybės užtikrinimą kiekviename procese naudojant įvairius prietaisus, tokius kaip lazerinis interferometras ir lazerio galios matuoklis.

Mechaninio surinkimo procese naudojamas lazerinis interferometras, lazerinis kolimatorius, ciferblato indikatorius ir marmurinė plokštė; Lazerinio surinkimo procese naudojamas lazerio galios matuoklis ir optinis mikroskopas.